3D printers are a relatively new technology, first hitting the market in the early 1980s. They were used mainly for industrial applications but have since become more widespread, with consumer-grade models becoming available in the early 2000s.

The technology has continued to evolve, with new and improved printers hitting the market constantly. Some of the most recent advancements include 3D printing with multiple materials and using lasers to create finer details in prints.

3D printing has many potential applications, from creating prototypes and small parts to full-scale manufacturing. People use it to create everything from prosthetic body parts to food items. Here’s how it’s shaping the world today.

Rapid Prototyping

Rapid prototyping is a manufacturing process that uses 3D printing to create prototypes quickly and efficiently. Manufacturers use it to develop prototypes for new products, allowing designers to test different designs and see which ones work best. Rapid prototyping is essential today because it enables companies to bring their products to market faster. It is also a vital part of innovation, allowing for more experimentation and creativity.

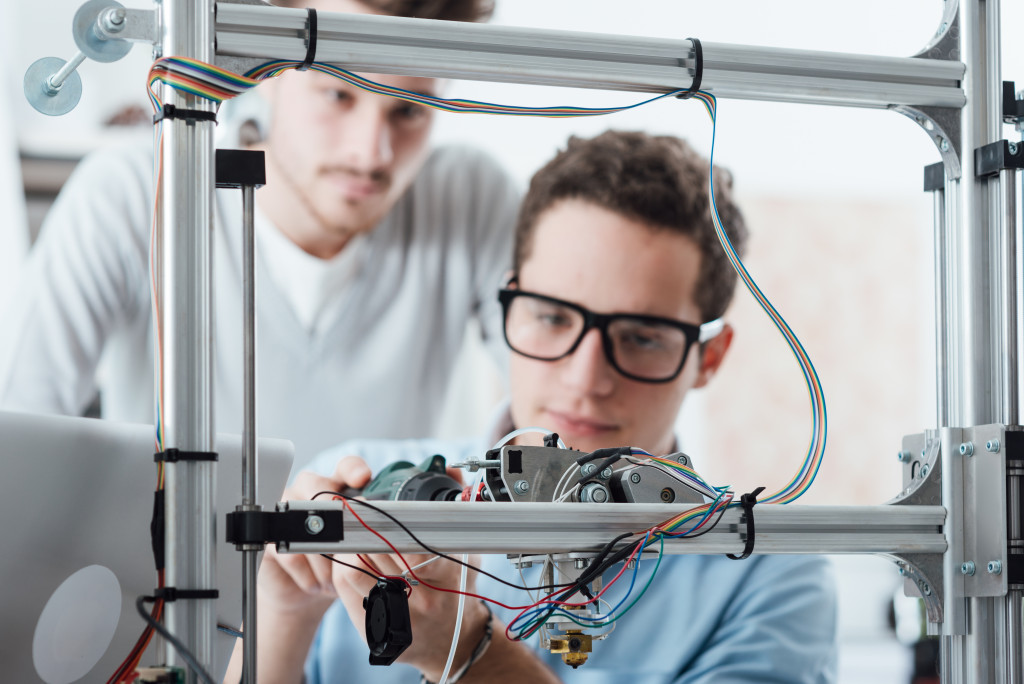

The process begins with a 3D model of the product being created. It can be done using various software programs or scanning an existing object. Often, people use CAD for modeling. People then print the model using a 3D printer.

Rapid prototyping has several advantages over traditional methods of prototyping. It is much faster and can be used to create complex shapes that are difficult or impossible to create with other methods. It also allows designers to test out different versions of their products quickly and easily.

Small-scale Manufacturing

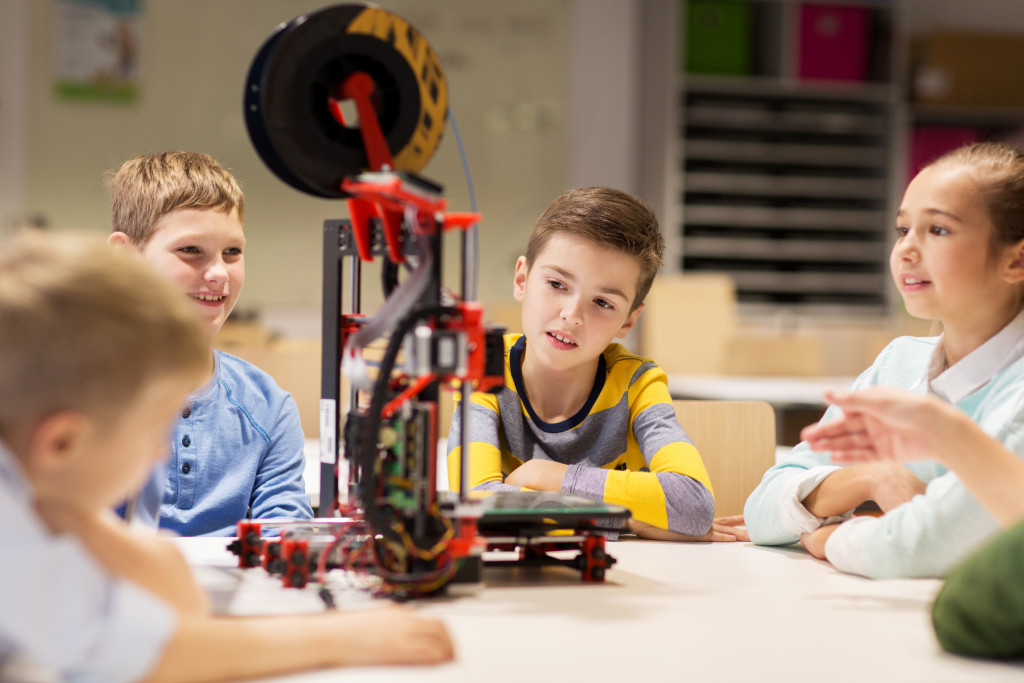

3D printing can also be used for small-scale manufacturing. It means creating products in small quantities, usually less than 100. This is often done using additive manufacturing, which builds up objects layer by layer. People can use it to print with various materials, including metals, plastics, and human cells. One well-known small-scale manufacturing market is in the field of orthodontics.

Orthodontic appliances are essential for dentists. One important appliance that every orthodontist must make is tooth implants. Before, it used to take around two weeks to manufacture a single tooth implant. But additive manufacturing has reduced that time to just 24 hours. This is a significant reduction in time and cost, and it’s thanks to 3D printing.

Another area where small-scale manufacturing is taking off is the creation of eyeglasses. In the past, glasses were made by hand, which was time-consuming and expensive. But now, 3D printing is used to quickly and cheaply create custom eyeglasses. This is benefiting both consumers and businesses alike.

Personalized Medicine

Personalized medicine is an emerging field that uses 3D printing to create customized medical products. It includes things like implants and prosthetics, as well as medication.

3D printing is particularly well suited for creating personalized medical products because it can create complex shapes and customize them to the individual’s specific needs. For example, 3D-printed implants can be made to match a patient’s bones perfectly. As a result, it results in a much better fit and fewer complications.

3D-printed medication is also becoming more common. It involves printing medicines in the form of pills or capsules. This advantage is that it allows for a high degree of customization. For example, if a patient has a rare allergy, people can print their medication without the allergen.

It’s just the beginning of personalized medicine. As 3D printing technology evolves, we will likely see even more impressive and life-changing applications in this field.

Full-scale Manufacturing

3D printing is also being used for full-scale manufacturing. It means creating products on a large scale, usually in quantities over 100.

One company that is using 3D printing for full-scale manufacturing is Tesla. Tesla is a car company that makes electric cars. They use 3D printing to create the parts for their vehicles. This includes things like the door handles and air vents. Tesla can print these parts quickly and cheaply. And because they are made with 3D printing, they can customize them to the customer’s specific needs.

It’s just one example of how 3D printing is used for full-scale manufacturing. As the technology continues to develop, we will likely see even more companies using it to create products on a large scale.

3D printing is a versatile technology that has many applications in different industries. It is used in many industries, often changing them along the way. As the technology continues to develop, people can expect to see even more impressive and life-changing applications of 3D printing.