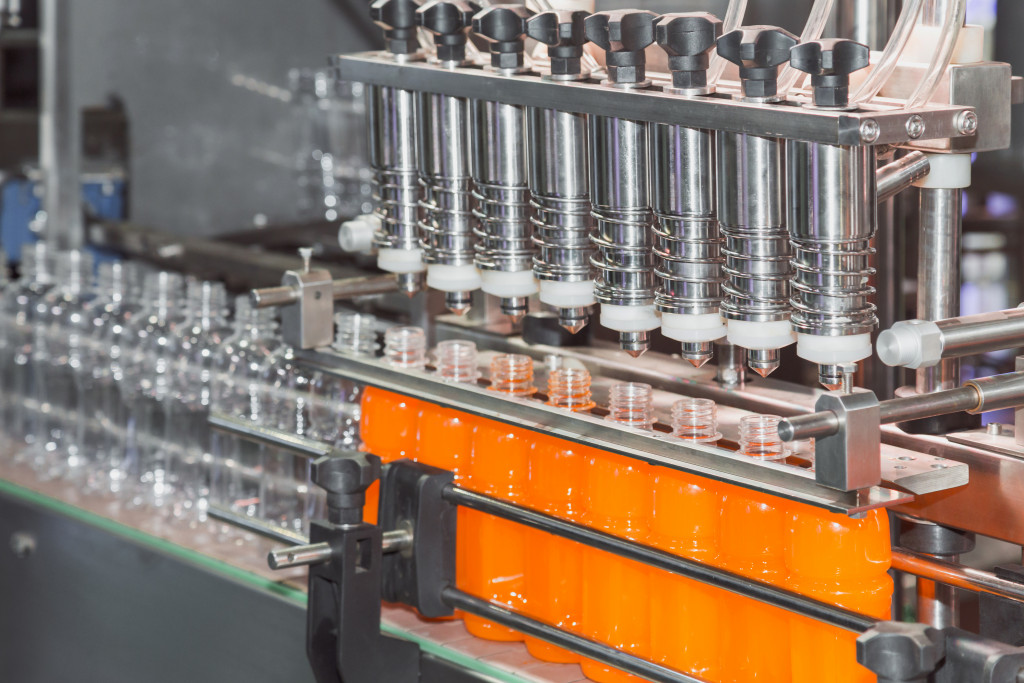

Filling machines are used to transfer liquids, powders, granulated solids, and other products into containers. There are many uses for these machines, including filling beverage cans, printer cartridges, or medicine bottles or packages. This technology can also be used for filling liquid soap dispensers in hotels, the oil tank on a lawnmower with engine oil, and much more.

It is important to maintain filling machines, especially in manufacturing plants, so that they continue to work properly. Proper maintenance includes regular inspection, cleaning, and lubrication of all moving parts. The best way to keep your machine working well is by following the manufacturer’s instructions on how often it should be serviced.

It’s no secret that filling machines are a huge part of the beverage industry, but what do filling machines do? One thing filling machines do is make sure bottles and cans get filled with the right product. Maintenance is very important to keep your machine in top shape to continue producing high-quality products. If you’re looking for more information on filling machines, then this blog post will be perfect for you.

Maintenance Tips for Filling Machines

Many filling stations are plagued with a variety of issues, such as low production or poor safety. Filling machines are an important part of filling station operations. Most stations have at least one filling machine, but it’s often neglected because the person who works there does not understand its importance in the business.

As such, many people don’t know how to use them or maintain them properly. If you’re looking for the best way to fix these problems and improve your overall filling station operations, then it’s time to invest in new equipment. You can also regularly replace and repair attachments for piston fillers and other parts to help you keep your machine running. Below are tips on how to maintain these machines properly:

Ensure that filling machines are always clean: This is very important because these machines are often used to fill products in processes that may carry a risk of contamination. For example, filling water bottles with drinking water can lead to contaminated drinks if the filling station is not properly maintained.

– Keep filling machines in good condition: For filling stations to work well and efficiently, they need proper maintenance. This includes lubricating them on a regular basis and checking the station for any flaws to make sure that it is working properly.

– Check filling machines on a regular basis: It’s important to check filling stations regularly since they can stop functioning if there are any malfunctions or other issues with them. Checking machines often allow you to identify and fix these things before they cause major problems, such as delays in filling products.

– Perform maintenance on filling machines: To perform this type of maintenance, fillers need to have a feature that allows users to remove filling heads and cylinders from the filling machine for cleaning purposes. It is also advisable that people lubricate them with oil or grease so that these parts can function smoothly.

– Investing in new parts: Investing in new parts is necessary when filling heads and cylinders that need to be replaced. As filling machines are used, filling heads tend to wear down over time from normal use as they’re constantly being put in place for filling purposes. This leads to the filling head not providing a proper seal on top of the cylinder anymore or becoming too loose at some point during usage, resulting in droplets of filling material leaking out. This can be fixed by replacing the filling head with a new one, which is much more reliable and doesn’t present these problems anymore.

Benefits of Filling Machines

Filling machines come with many benefits, including filling up containers much more quickly than filling them up by hand. This can be especially beneficial for bottles of many shapes, sizes, and materials, which would make filling each one individually a chore when doing it by hand. Furthermore, these machines come with enough pressure to keep the material in place during usage. This means that they won’t need to be constantly adjusted. This also eliminates the risk of leaks.

These machines are also beneficial for those who are looking to save on labor costs in their businesses. The machines can fill containers on their own instead of hiring a worker to do it or outsourcing this task to an outside company, which would be more costly than purchasing a reliable filling machine.

Investing in Filling Machines

Entrepreneurs who make use of filling machines will benefit from filling machines in a variety of ways. One way filling machines will help entrepreneurs is by allowing them to save on labor costs, which can be expensive when outsourcing or hiring workers to fill containers for their businesses. Filling machines also allow their users to do so with little pressure needed and as quickly as possible. This contributes to increased productivity and convenience for workers.