- IoT integration allows for predictive maintenance, optimal resource utilization, and informed decision-making.

- Advanced robotics and automation uses cobots, articulated robots, cartesian robots and AMRs for increased productivity and product quality.

- AI and machine learning enable data-driven decisions to optimize processes and predict future market demands.

- 3D Printing allows for rapid prototyping and customization of products.

- Tabletop filling machines provide accurate, consistent, and swift packaging operations.

In the dynamic landscape of the industrial sector, staying ahead often means embracing innovation. As you navigate the complex web of operations, efficiency and productivity, become pivotal. Leveraging the right technologies can transform your processes, reducing costs and amplifying outputs. Ready to usher your industrial operations into the future? Here’s a dive into five game-changing technologies that promise to streamline and redefine how industries function.

1. IoT (Internet of Things) Integration

Harness the power of connected devices; the future is intertwined.

IoT, or the Internet of Things, refers to the network of interconnected devices, machines, and objects that collect and share data. Integrating IoT into your industrial operations allows you to monitor and analyze machinery and processes.

This technology allows for predictive maintenance, alerting you to potential machine failures before they occur, saving time and money. Moreover, IoT enables optimal resource utilization, ensuring that energy, manpower, and materials are used efficiently. When every device communicates and offers insights, decision-making becomes informed, swift, and impactful.

2. Advanced Robotics and Automation

Let machines shoulder the burden; they’re designed for precision and endurance.

Industrial robots have evolved beyond mere mechanical arms. Today’s robots come equipped with advanced sensors, AI capabilities, and intricate programming, allowing them to perform complex tasks with unparalleled precision. Robots can handle many functions, from packaging to assembly to inspections, often outpacing human capabilities.

Here are some examples of advanced robotics in the industrial sector:

Collaborative Robots (Cobots)

Collaborative robots, or cobots, are designed to work alongside humans in a shared workspace. Cobots are equipped with advanced safety features and sensors, enabling them to stop or slow down when a human is nearby. This collaboration of humans and robots optimizes productivity by combining human flexibility and problem-solving skills with robotic precision and endurance.

Articulated Robots

Articulated robots have rotary joints that allow for a full range of motion. These robots are highly versatile and can perform tasks with intricate maneuvers, from welding and painting to pick-and-place operations. With their multiple axes of rotation, articulated robots offer flexibility and high-precision operations, leading to improved product quality.

Cartesian Robots

Cartesian Robots, also known as gantry or linear robots, operate within a three-dimensional space using linear movements along the X, Y, and Z axes. They are primarily used in assembly operations, machine tool handling, and palletizing, providing a reliable and efficient solution for repetitive tasks requiring high consistency.

Autonomous Mobile Robots (AMRs)

AMRs are robots that can navigate and operate without human intervention within a facility. They use sensors and onboard computing power to understand their environment and plot the most efficient routes. AMRs are often used for material handling and transportation tasks, significantly reducing manual labor and improving workplace safety.

3. Artificial Intelligence (AI) and Machine Learning

Unleash the power of data-driven decisions; let machines learn, adapt, and optimize.

Incorporating AI and machine learning into industrial operations can be transformative. These technologies analyze vast amounts of data, deriving actionable insights to refine processes. Whether optimizing supply chains, enhancing product quality, or predicting market demands, AI equips you with foresight.

Moreover, machine learning algorithms adapt over time. They learn from past patterns, continuously refining their predictions and suggestions. By integrating AI and machine learning, you’re streamlining operations and future-proofing your industry, ensuring that you’re always several steps ahead.

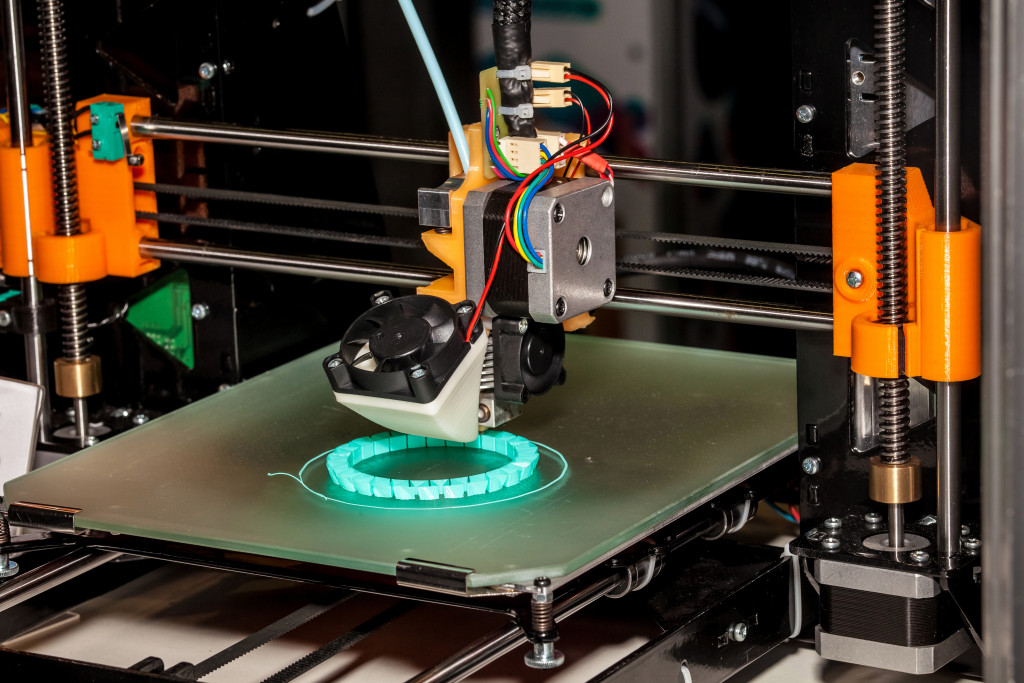

4. 3D Printing for Rapid Prototyping

Transform ideas into tangible prototypes; the future is just a print away.

3D printing, or additive manufacturing, has revolutionized how industries approach product design and prototyping. Gone are the days of lengthy waits for prototypes. With 3D printing, you can transform digital designs into physical objects swiftly.

This rapid prototyping means that design flaws or potential improvements can be identified quickly, reducing product time-to-market. Moreover, 3D printing allows for customization. 3D printing caters to unique needs without traditional manufacturing constraints, whether a specific component or a tailor-made product.

5. Efficient Packaging Machines

Precision, efficiency, and consistency are all compacted in one machine.

Packaging often becomes a bottleneck in industrial operations, especially when precision is paramount. This is where investing in a high-quality tabletop filling machine becomes significant — a compact yet powerful technology for accurate, consistent, and swift filling operations. Especially beneficial for industries dealing with liquids, these machines ensure that each container, whether a bottle or a pouch, is filled to the exact required volume.

Beyond accuracy, tabletop filling machines are versatile. They can handle various container shapes and sizes, ensuring adaptability across products. Moreover, their compact design means they can easily integrate into existing production lines without demanding extensive space. Incorporating this technology enhances packaging efficiency and ensures product consistency, elevating customer trust and satisfaction.

In Summary

Modernizing your industrial operations is more than just a competitive advantage; it’s necessary in today’s fast-paced world. Embracing these technologies streamlines processes and positions your business for future challenges and opportunities. Dive into the tech-driven future and witness your industrial operations transform from conventional to cutting-edge. With innovation as your ally, every challenge becomes an opportunity, and every process is a testament to efficiency.