The United States has long been a world leader in manufacturing. In recent years, however, the sector has faced significant challenges. A strong dollar, rising labor costs, and increased competition from China and other countries have led to a decline in manufacturing jobs and output.

Despite these challenges, the United States remains one of the world’s top manufacturing nations. The country is home to many of the world’s largest companies and most advanced technologies. And while manufacturing job losses have been substantial, the sector still employs more than 12 million workers—about 8% of the U.S. workforce.

To deal with these challenges of competition, the pandemic, and a deteriorating workforce. Therefore, the industry aimed its investments towards technology.

The manufacturing industry is one of many industries utilizing technology to increase its output. Here are various technological innovations being used in the field of manufacturing today.

3D Printing

3D printing is making three-dimensional solid objects from a digital file. It is also known as additive manufacturing. The object is created by adding layers of material one at a time until the desired shape is achieved. Moreover, certain parts, such as classical hold-down clamps, can be printed more efficiently through this process. This can decrease the costs of bigger products and equipment.

3D printing has been used in the manufacturing industry for some time now to create prototypes and small-batch production runs. However, in recent years, the technology has become more sophisticated and is now being used to create larger objects such as car parts and airplane components.

More factories are using 3d printing. This particular tech can also make small manufacturing companies more competitive. 3d printers are becoming faster and more efficient. They are also much cheaper, making them affordable for smaller companies.

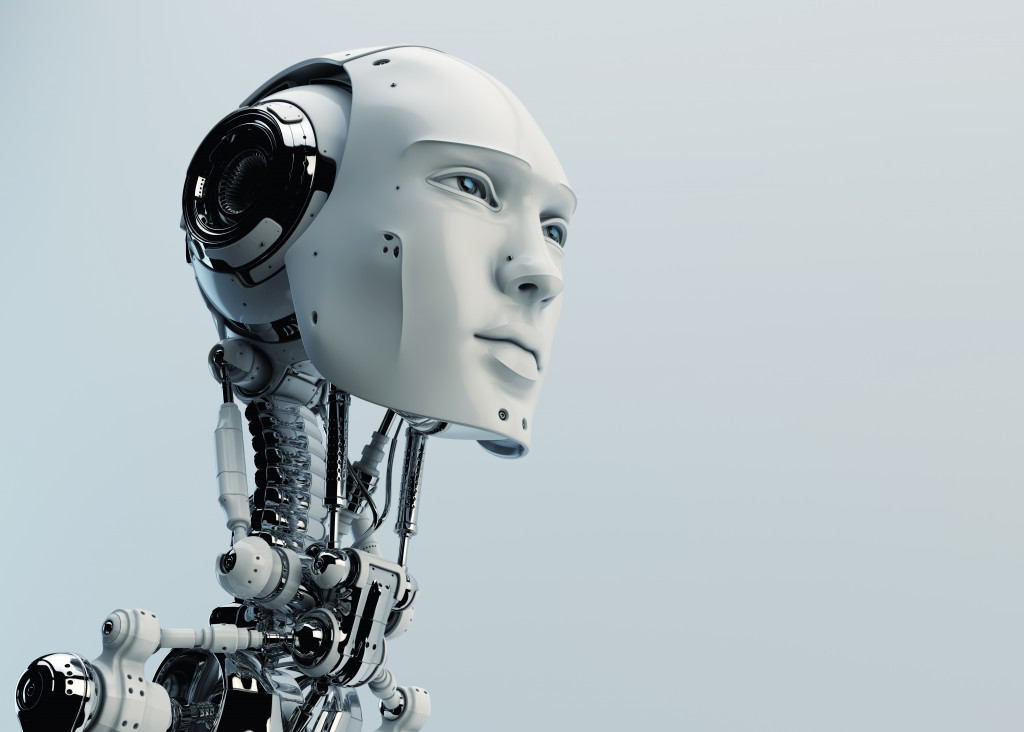

Robots

Robots are machines that can be programmed to carry out various tasks. They are commonly used in manufacturing to perform dangerous, complex, or repetitive tasks. For example, robots can weld, paint, assemble, and test products. They can also be used to package and label products. It’s been known by many experts that robots are already increasing productivity today.

In recent years, there has been a surge in robots being used in factories. This is partly due to the falling cost of robotics and the increasing demand for robots from companies looking to increase efficiency and reduce costs. As a result, many factories are now using robots to perform tasks previously done by human workers.

The use of robots in manufacturing is not without its challenges, however. One challenge is the high cost of robots. Another challenge is that robots can cause job losses by replacing human workers.

Despite these challenges, robots in manufacturing are expected to continue to grow in the years ahead. This is because robots are becoming more affordable and capable of performing various tasks.

AI and Machine Learning

Artificial intelligence (AI) and machine learning are technologies used to create and interpret human-like or machine-like responses. For example, AI can be used to develop software that can make decisions independently. On the other hand, machine learning is a type of AI that allows the software to learn from data and improve its performance over time.

AI and machine learning are being used in manufacturing to create intelligent machines that can make decisions independently. These technologies are being used to develop robots that can learn from data and improve their performance over time. In addition, AI and machine learning are being used to create software that can help factories run more efficiently.

The use of AI and machine learning in manufacturing is still in its early stages. However, these technologies are expected to impact the industry in the years ahead significantly. This is because they are becoming more sophisticated and can perform more complex tasks.

Virtual Reality

Virtual reality (VR) is a technology that allows users to experience a simulated environment. VR can be used to create virtual worlds that users can interact with. It can also be used to create simulations of real-world settings.

VR is being used in manufacturing to create virtual worlds that users can interact with. These virtual worlds can train workers on how to operate machinery or perform tasks. They can also be used to test products before they are released to the public. Its also being used to create simulations of real-world environments. These simulations can be used to help factories run more efficiently and reduce the need for physical prototypes.

The use of VR in manufacturing is still in its early stages. However, it is expected to have a major impact on the industry in the years ahead.

The future of manufacturing is looking very bright. With the advancement of 3d printing, robotics, artificial intelligence, and virtual reality, factories are becoming more efficient and productive. These technologies are expected to have a significant impact on the industry in the years ahead.